Printed circuit boards (PCBs) are at the heart of almost every electronic device. But what happens before they get to your hands? A lot of planning, cutting, and assembling takes place. A critical part of the manufacturing process is something called V-scoring. If you’re building your electronics or just curious about how things work, this blog will help you understand why V-scoring is so vital in PCB manufacturing.

V-scoring is a method used by PCB manufacturers to help separate individual circuit boards from a larger panel. Imagine baking a batch of cookies and then cutting them into pieces before serving. That’s pretty much what V-scoring does only with circuit boards.

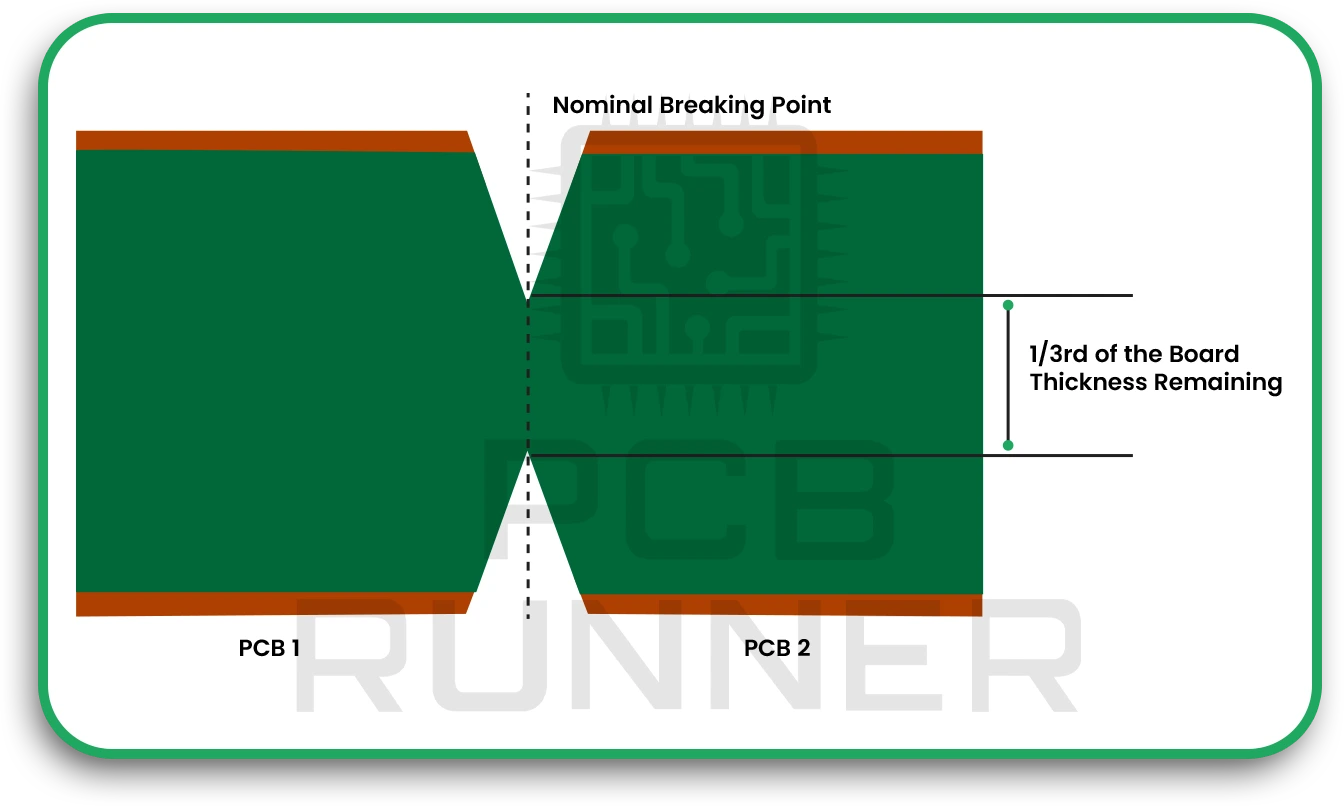

It involves making V-shaped grooves on both sides of the board. These grooves are not deep enough to cut all the way through. Instead, they make it easier to snap the boards apart cleanly after assembly.

When PCB assemblers make multiple boards at once, they put them all in one large panel. This helps with quicker assembly and better handling. Handling single boards one at a time would be slow and costly. That’s why PCB board manufacturers often design multiple boards on a single panel.

Once everything is soldered and tested, the boards are separated. That’s where V-scoring or other methods like routing come in. But V-scoring is often faster and cheaper.

It’s easier to work on a panel with several boards than on single pieces. Pick-and-place machines can handle them more quickly.

After assembly, the boards can be snapped apart easily without special tools.

It uses less space and fewer tools, which means lower costs.

V-scoring makes better use of board material. Less waste is always a good thing!

V-scoring works by cutting shallow V-shaped grooves into both the top and bottom of the board. These grooves weaken the board just enough to let it snap apart when needed. But they still leave the panel strong enough to handle during assembly.

V-Scoring vs. PCB Jump Scoring

You might also hear about something called PCB jump scoring. This is a special kind of V-scoring where the groove doesn’t run all the way across the board. Instead, it “jumps” over sensitive areas. This helps protect certain parts while still allowing for separation.

Both V-scoring and jump scoring are used by professional PCB assemblers, depending on the design and purpose of the board.

V-scoring works best when your boards:

If your design is round or has curves, other options like routing might be better.

If you’re working with a PCB board manufacturer, here are a few things to keep in mind:

PCB Runner has been a trusted PCB manufacturer and PCB assembler in the UK and Europe for over 10 years. Whether you’re working on a custom PCB or a whole circuit board assembly, we handle everything under one roof.

With PCB Runner, you don’t need to worry about your V-scoring requirements. Our team checks your files and helps you decide the best method for board separation. We don’t just manufacture; we also support your design process. We even offer 24-hour tech support so that you can get help anytime.

Our facility is certified with ISO9001 and qualified for IPC Class 2, 3, and 3A. We serve industries like aerospace, defence, medical, and more. Whether your boards are for hobby projects or critical systems, PCB Runner delivers quality.

We also support advanced features like PCB jump scoring when your design needs special care. If your design includes delicate components near the edge, we can work with you to avoid damage during board separation.

V-scoring may seem like a small part of the PCB manufacturing process, but it plays a massive role in making things faster, cheaper, and more reliable. If you’re planning to get boards made, ask your PCB board manufacturer about V-scoring. It might be just the feature you need.

Working with an experienced partner like PCB Runner makes everything easier. We understand every detail, from circuit board assembly to advanced scoring techniques. Whether you’re a beginner or a pro, our team is here to help you every step of the way.

So next time you order PCBs, don’t forget to ask about V-scoring. It could save you time, money, and stress.

2025-2028(c)Copyright PCBRPT Ltd., Call us +86 75529752926 Mon-Fri: 24 hours, Sat: 9am-6pm, GMT+8

Visit our office: Room 401, Building 5, Xunyuan Zhichuanggu Industrial Park, Fengtang Avenue, Fuhai Street, Bao'an District, Shenzhen, Guangdong

Visit our factory: AD6 District, Dongsheng Industrial Park, Meizhou City, Guangdong Province

Support by : Zhdr.Net | SiteMap