The electronics industry is advancing rapidly, and high-density interconnect (HDI) flex circuits are at the heart of this transformation. These advanced flex and rigid PCB designs are making electronic devices smaller, lighter, and more powerful. From smartphones and wearables to aerospace and medical equipment, HDI flex circuits are shaping the future of technology.

For PCB circuit board manufacturers, keeping up with the latest HDI PCB technology is essential to stay competitive. This blog will discuss what makes HDI flex circuits special, their key benefits, and why they are becoming the new standard for PCB design.

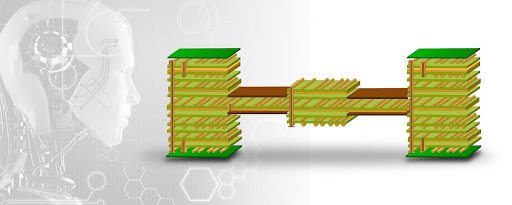

HDI (High-Density Interconnect) flex circuits are a type of printed circuit board with a higher wiring density than traditional PCBs. They combine flexible and rigid PCB sections, allowing them to fit into compact spaces while maintaining strong electrical connections.

Unlike traditional multilayer PCBs, which rely on significant traces and through-hole vias, HDI PCB technology uses microvias, blind vias, and buried vias to create smaller, more efficient circuits.

One of the most significant advantages of HDI circuit design is miniaturization. Because these circuits use microvias and thinner traces, they take up less space. This allows manufacturers to make smaller, lighter devices without sacrificing performance.

High-density interconnect flex circuits have shorter signal paths, which reduce signal loss and improve transmission speeds. This makes them ideal for high-speed applications, such as 5G networks, aerospace systems, and medical devices.

Why it matters: The shorter the signal path, the less interference and signal degradation you experience. This is crucial for advanced electronics that require precision and reliability.

Traditional PCBs can crack or break when exposed to vibration, bending, or extreme temperatures. HDI flex circuits, however, are designed to be more durable.

How?

While HDI flex circuits may cost more upfront due to advanced manufacturing processes, they actually save money in the long run.

How?

As the demand for smaller, faster, and more efficient electronics grows, PCB circuit board manufacturers must adapt. Germany’s HDI market, for example, is rapidly expanding, with industries like automotive, industrial automation, and IoT devices embracing the technology.

Here’s why HDI flex circuits are the future:

The shift to high-density interconnect flex circuits isn’t just a trend—it’s a necessity for next-gen electronics.

While the benefits are clear, HDI PCB technology comes with its challenges. PCB circuit board manufacturers need specialized equipment and expertise to produce these advanced boards.

When selecting a PCB circuit board manufacturer for your HDI flex circuits, consider the following:

A trusted PCB board manufacturer will help you navigate the complexities of HDI PCB technology, ensuring you get a high-quality, reliable product.

HDI flex circuits are revolutionizing the PCB industry, enabling smaller, faster, and more powerful electronics. With benefits like superior performance, increased reliability, and cost savings, they are becoming the go-to solution for next-generation devices.

For PCB circuit board manufacturers, adapting to HDI PCB technology is not just an option; it’s the future. Whether you’re designing smart wearables, medical devices, or high-speed computing systems, investing in high-density, interconnect flex circuits will set your products apart.

At PCB Runners, we specialize in HDI flex circuits and custom-printed circuit boards for a wide range of industries. Contact us today for expert guidance and high-quality PCB solutions!

1. What is an HDI Flex Circuit?

An HDI flex circuit is a type of printed circuit board with higher wiring density, allowing for compact, flexible designs with superior electrical performance.

2. Why is HDI PCB Technology Better Than Traditional PCBs?

HDI PCBs use microvias, thinner traces, and advanced materials, resulting in smaller, faster, and more reliable electronic devices.

3. What Are the Main Applications of HDI Flex Circuits?

They are used in smart devices, medical equipment, aerospace systems, automotive electronics, and 5G infrastructure.

4. Are HDI Flex Circuits Expensive?

While initial costs are higher due to complex manufacturing, long-term savings in reliability and efficiency make them cost-effective.

5. How Can I Find a Reliable HDI PCB Manufacturer?

Look for experience with HDI technology, industry certifications, and advanced testing capabilities to ensure high-quality, reliable PCB production.

2025-2028(c)Copyright PCBRPT Ltd., Call us +86 75529752926 Mon-Fri: 24 hours, Sat: 9am-6pm, GMT+8

Visit our office: Room 401, Building 5, Xunyuan Zhichuanggu Industrial Park, Fengtang Avenue, Fuhai Street, Bao'an District, Shenzhen, Guangdong

Visit our factory: AD6 District, Dongsheng Industrial Park, Meizhou City, Guangdong Province

Support by : Zhdr.Net | SiteMap